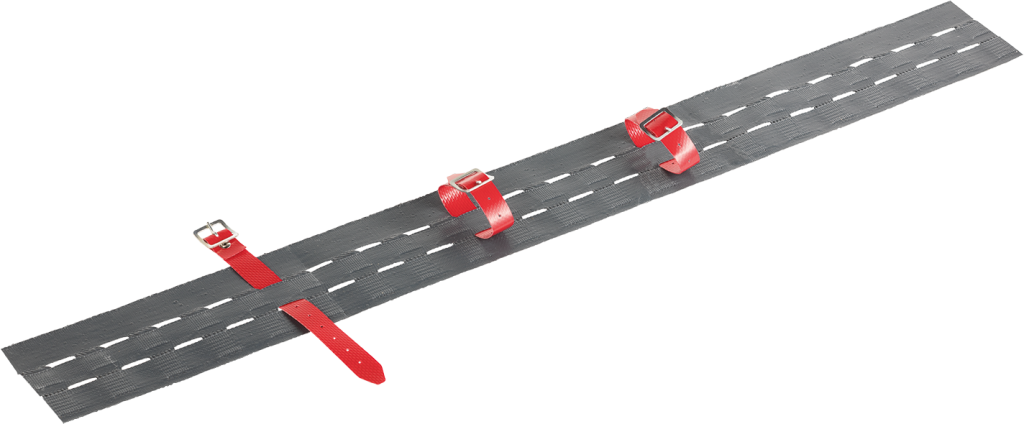

Webbing with loops in sliding roofs:

Using a special weaving technique, we produce our webbing in which tabs are woven every 2 cm. This means the strap can simply be welded onto the hood and the buckle straps can be pulled through. The time-consuming assembly of conventional weld-on corners is no longer necessary. This reduces your manufacturing times and thus the production costs of the convertible tops. If a loop should tear out due to external influences such as wind, the tarpaulin can be securely fastened again simply by moving the strap. In the case of minor damage, extensive repairs in the workshop are therefore not necessary. By using our webbing, the connection of the belts is significantly stronger and more durable than conventional products made of tarpaulin. The product has been tested and approved by leading vehicle and roof manufacturers.

Webbing with loops in tents:

Due to the tear strength of approx. 110 kg per loop, our webbing with loops is used in a variety of ways in tent construction. Among other things, for mounting ceiling lights or as a storage system for the wall.